20 Middleburgh Street, Troy, NY 12180 • 518-272-0773

High Efficiency Enhanced Boiler

ABSTRACT

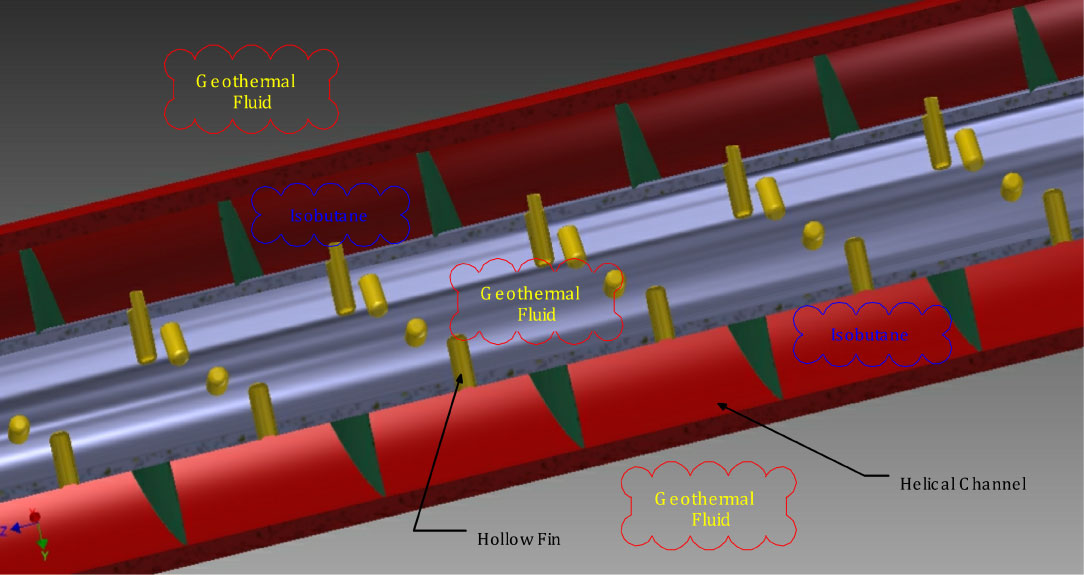

For devices known in the art, “conventional boilers”, “waste heat recovery boilers”, and “heat exchangers” usually require many small tubes making successive passes within the device. The embodiment of the invention, replaces numerous conventional small tubes with an enhanced conduit. The enhanced conduit incorporates a helical channel and a system of fins parallel to the channel, each fin may extend through the wall of the enhanced conduit. In one embodiment, the heat transfer medium is flowing contrary to the heat transfer fluid. A similar embodiment places the heat transfer medium and the heat transfer fluid in concurrent flow. The design enhances the heat transfer relationship between the heat transfer fluid and the heat transfer medium through a system consisting of coiled channels and a plurality of fins uniform to the channel that direct the fluids in a method that will enhance the heat transfer.

The High Efficiency Enhanced Boiler is absolutely the greatest heat exchanger to reach the modern market. Simply stated the HEEB exchanger is extremely efficient, but even more impressive is that it is adaptable in a way that maximizes efficiency relative to the application. The HEEB exchanger is configurable across a wide range of pressures, temperatures, and environments able to maximize energy savings with a cost-effective design. The time is now, allow us to provide you with the most efficient, adaptable, and cost-effective solution for your clean-energy needs.

The HEEB exchanger is a green energy solution. First by understanding (not ignoring) the problems associated with fossil fuels, we realize HEEB exchanger offers a compact solution to help heal our stressed planet. Geothermal is one of a few systems currently available that generate energy without emitting any greenhouse gasses. For the interested reader, I describe a HEEB-type exchanger that cleanly and efficiently extracts enough energy to power a one megawatt generator. The scheme is familiar, that is the heat transfer medium ( Isobutane at six hundred pounds per square inch) is circulated between a turbine and a HEEB exchanger. The fundamentals of the process proposed herein are centered about the HEEB exchanger transferring heat between a geothermal fluid (modeled as water at 250F) and the heat transfer medium (IsoButane range 50F to 175F @ 600 psi). Geothermal fluid surrounds the Isobutane flowing through the helical channels, illustrated below.

Immersion of the HEEB exchanger in geothermal fluid increases the surface area, which allows the heat transfer to be further enhanced. The helical channel provides the Isobutane heat transfer coefficient with a turbo boost. In addition the hollow fins direct the two fluids into an intimate setting of high heat transfer coefficients and thin wall sections. These attributes combined justify the HEEB exchanger as the most efficient and adaptable heat transfer device on the market. To illustrate this assertion, the finite element analysis models the expected heat flux below.

For this example, the HEEB exchanger would require only thirty-five feet over all length, while a non-enhanced counterpart would require more than double for this exact application. If the thermal pool was at a higher potential the HEEB exchanger would be even more compact. For thermal pools in the 500° Fahrenheit or higher range a more favorable heat transfer medium of high pressure hot water would be suitable. However, this may require suspending the HEEB exchanger above the hot cauldron. In any event, the HEEB exchanger can be designed to meet the demands of the specific environment chosen for the heat source.

The rules of fabrication are based upon the ASME Section VIII Division 1 Code using common materials. The materials above are common stainless steel pipe, sheet, and Round stock. The hollow fins are machined with a slight taper on the outer diameter that press-fit into a corresponding tapered hole on the inner pipe. This arrangement is pressure tight, however it can be improved by seal welding the joint. The fabrication of the HEEB exchanger is as stated, ASME Code fabrication with common materials designed to keep costs low and efficiencies high.

The High Efficiency Enhanced Boiler is absolutely the greatest heat exchanger to reach the modern market. Simply stated the HEEB exchanger is extremely efficient, but even more impressive is that it is adaptable in a way that maximizes efficiency relative to the application. The HEEB exchanger is configurable across a wide range of pressures, temperatures, and environments able to maximize energy savings with a cost-effective design. The time is now, allow us to provide you with the most efficient, adaptable, and cost-effective solution for your clean-energy needs.

If you have any questions regarding this case study or have another application that you would like to discuss feel free to contact us at John@TroyToolandEngineering.com or JEOkonski@TroyBoilerWorks.com.